Everything you need to know about our Magnets

How our Magnets are Produced

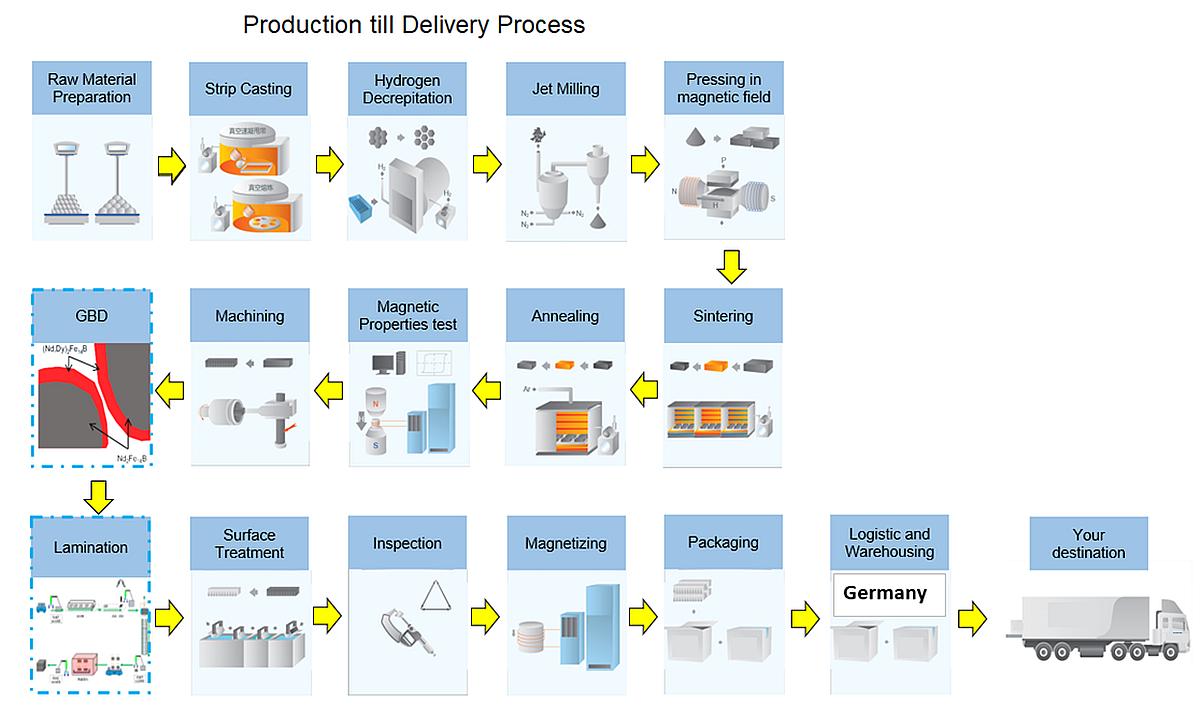

Our production process flow uses the best available technologies for each step

NdFeB or SmCo magnets are manufactured using a sophisticated process that involves some very highly technical metallurgical methods, including powder metallurgy and advanced process metallurgy.

Different processes are used to achieve the properties required for the different grades. These variations include differences in composition, morphology (crystal shape) and process.

Many of the most important processing steps are explained below.

Manufacturing processes of NdFeB or SmCo magnets

The production of neodymium magnets depends on advanced materials technology and processes. Here are the most important steps:

- Rare earth ore is discovered and mined.

- The ore is processed and refined.

- Elements are added to the refined metal to produce a rare earth alloy

- Smelting (raw material) and strip casting

- Hydrogen depletion

- Beam milling

- Pressing under external magnetic field

- Cold isostatic pressing

- Sintering

- Annealing

- Machining and grinding

- Plating/coating

- Magnetizing

- Packaging and shipping

- Processing steps for neodymium magnets

There are many important production steps in the manufacture of high-quality, high-tech neodymium magnets - and numerous sub-steps. Each step is extremely important, and each step is an essential part of a highly sophisticated process.

Grain boundary diffusion

As an additional technology for achieving best quality performance magnets, can be manufactured with a very specialized grain boundary diffusion technology. It is more expensive, but lead to better magnet performance, and thus to a better price by higher performance values.

In recent years, some leading NdFeB magnet manufacturers have produced NdFeB magnets without HREEs (or with greatly reduced HREEs) for high temperatures and higher coercivities by improving control over grain size and shape and using grain boundary diffusion.

Grain boundary diffusion (GBD) is a method of selectively introducing HREEs into the grain boundary phase of the magnet. GBD achieves high coercivity with greatly reduced amounts of HREEs such as dysprosium and terbium, alleviating concerns about the use of these rare and expensive HREEs.

Shape and size of the crystals

In many metallurgical systems, material properties are influenced by the shape of the individual crystals - or grains - in the metal structure, as well as the average shape and size of the grains in the overall microstructure. Tight control of processes can lead to improved magnetic properties at high temperatures while reducing the need for HREEs.

Each manufacturing process must be carefully monitored to ensure that each step is carried out with precision to achieve quality, performance and economy.

The production of NdFeB magnets requires large investments

These processes require large investments in equipment. For example, vacuum belt casting equipment, hydrogen deposition equipment, jet milling equipment, magnetic orientation presses, cold isostatic presses, and sintering and annealing furnaces are required just for the production of magnetic ingots. Each of these factors represents a considerable investment.

Very precise cutting, processing and grinding machines cut the magnetic blocks to size. Since the magnet material is prepared through a powder metallurgy process and possibly other processes, the parts have already experienced a considerable increase in value by the time they reach the machining and grinding processes.

The cutting is very carefully planned. Wire cutting is done with very thin wire to minimize cutting losses. Grinding is done when necessary, but it is well planned to minimize material loss.

Electroplating and other coating processes require a significant capital investment to produce high quality products in an economical and environmentally friendly way.

Detailed Process Steps Explained

Step 1: Mining rare earth ore

First, the rare earth ore is discovered and then mined. Most rare earth mines are open pit mines, which means that the ore is extracted using large equipment after the overburden has been removed.

Step 2: Ore processing and refining

Next, the rare earth ore is crushed and ground. Then the ore goes through a flotation process where it is mixed with water and special reagents to separate the rare earths from the residues. Depending on the origin of the ore, the concentrate can also be subjected to electrolytic refining. Rare earths can be refined and extracted electrochemically, by distillation, ion exchange or other processes before the concentrate (refined ore) is smelted. This means that it is heated to very high temperatures (~1500°C) so that the valuable metals can be separated from the unusable materials in the ore.

Rare earths are often associated with other valuable metals such as precious metals and even significant amounts of base metals such as copper and nickel, so several steps are required to separate them.

The extraction of rare earths is difficult as many of them have very similar properties, making refining a challenge. This is one of the cost factors, as refining methods require the use of expensive chemicals and time-consuming processes.

For example, it is not well known that about 20-30% of the neodymium in neodymium magnets is actually praseodymium. The alloy used to make magnets is called PrNd because these two elements are so chemically similar that they are not only too similar to be easily separated, but so similar that it would only make a small difference in the quality of the magnet.

Step 3: Alloying

During the alloying process, small amounts of other metals are added to the NdFeB alloy to refine and alter the microstructure of the final product, improving its magnetic properties and enhancing the effects of other processes.

Step 4: Strip casting

The alloyed NdFeB is now ready for melting and tape casting. It is heated in a vacuum furnace, and a stream of molten metal is forced under pressure onto a cooled drum, where it is rapidly cooled at about 100,000 degrees per second. The high cooling rate produces very small metal grains, which help to simplify and improve downstream processing. Small grains are also an important component in the production of high-quality magnets.

The NdFeB magnet material is quickly solidified in a vacuum belt casting furnace, resulting in very small grains.

Step 5: Hydrogen decrepitation

While the grains are very small in tape casting, the material comes out of the casting machine in the form of slabs that need to be crushed into powder to produce magnets. The next step is hydrogen desilication - a process in which hydrogen is added to deliberately break down the magnet material. The metal is now so brittle that it can easily be broken into smaller pieces, which is why it is also called hydrogen deposition. When processing most metals, fabricators avoid introducing hydrogen into the metals.

Hydrogen embrittlement can be a major problem for many metals. In this case, the hydrogen is intentionally introduced to break down the material. It is then easy to grind it even smaller in a subsequent operation. The decomposed material is now ready for the next step.

Step 6: Jet milling

The jet mill uses a high velocity stream of cyclone inert gas to grind NdFeB metal pieces into powder. The cyclone automatically classifies the particles by size as they pass through the system, maintaining a narrow - and very favorable - particle size distribution.

The cyclone airflow naturally separates the particles and prevents the material from coming into contact with the sides of the pressure vessel due to the pressure and speed of the gas flow, as different particle sizes have different aerodynamics.

The jet mill is a very clean and effective method to grind NdFeB metal into powder

Step 7 Pressing under external magnetic field

The powder is stored in an inert gas atmosphere and handled in glove boxes before entering the automatic press. The powder is placed in a mold and pressed between plates under a strong magnetic field, creating a block of material. The magnetic field aligns the grains so that the magnetic domains remain aligned in the intended direction during all subsequent processing steps.

The magnetic field can be aligned in two ways: Sintered neodymium magnets are usually pressed perpendicular to the block to achieve the highest anisotropy (strongest north-south magnetization)).

Step 8: Cold isostatic pressing

The block of material is packed in bags and immersed in a cold isostatic press (CIP) under high pressure. In this way, all remaining air gaps in the block are removed. The block leaves the press with a much smaller size than when it entered the press.

Step 9: Sintering

The pressed block is removed from the bag and sintered. During sintering, the blocks are fired in a furnace at a very high temperature just below the melting point of the metal. At this temperature of >1000oC, the individual atoms are very mobile so that the blocks can develop their full magnetic and mechanical properties.

The magnetic domains retain the same orientation as before sintering. At this temperature, full density is reached and the blocks have shrunk to their final size.

Step 10: Annealing

After sintering, stresses are built up in the metal due to the movements during sintering, so the blocks are heat-treated again in stages at lower temperatures to relieve the stresses.

The blocks are run up to a high holding temperature for a certain time and then run down to a lower holding temperature. Once the holding time is reached, the now stress relieved blocks are slowly cooled to room temperature.

Step 11: Cutting, processing and grinding

The NdFeB magnets have already been given a high added value by the previous steps. Cutting, machining and grinding is done according to a strict control plan and waste is minimized by design.

Wire cutting is done with very fine wire to minimize cutting losses. Machining and grinding are minimized by strict controls during the preceding processes. Waste material is reused and recycled.

Step 12: Surface treatment

Most neodymium magnets now undergo a final surface treatment before they leave the factory. The basic treatment is a nickel-copper-nickel electroplate, which protects the magnet from corrosion in most typical use environments.

Some end users choose not to use a coating at all for various reasons. Others specify coatings that provide a higher level of protection than Ni-Cu-Ni. Aluminum-zinc offers much higher protection than NiCuNi. IVD Aluminum is another choice specified by end users. Epoxy is a very good coating for intense environments and is specified by end users for applications where the magnets may be exposed to salt spray.

Step 13: Inspection

The magnet material is tested and evaluated at nearly every step of the process, and every data point is recorded. Given these intensive testing requirements, BJMT has an extensive inventory of testing equipment to maintain and improve product quality, production efficiency and cost.

Rigorous testing ensures that only the highest quality products are delivered to the customer

Step 14: Magnetizing

One of the final steps is magnetization. The material is placed in an electric coil, which is energized to create a very strong magnetic field for a short period of time. After the coil is switched off, the magnetic field remains in the magnet.

Differences in the composition and processing of NdFeB

High-temperature neodymium magnets generally require the addition of heavy rare earth elements (HREE) such as dysprosium and terbium. The HREEs improve the magnet's resistance to demagnetization at high temperatures and in the presence of opposing magnetic fields.

The relative rarity of HREEs has led some of the leading NdFeB companies to develop methods and processes to reduce or eliminate the need for HREEs in high-temperature NdFeB magnets.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.